COMMITMENT

Customer commitment

Read More...

INTEGRITY

Highest standards of integrity

Read More...

QUALITY

Unsurpassed products & services

Read More...

TEAMWORK

See What We're Up To

Read More...

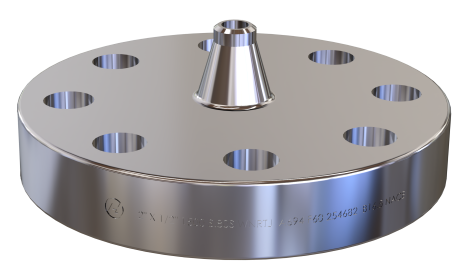

SIZES: ½” to 24”

SIZES: ½” to 24”

CLASS: 150 to 2500

TYPE: Reducing Weld Neck, Reducing Slip-On, Threaded Reducing Flanges

SCHEDULE: S10, S20, S30, S40, S STD, S60, S XS, S80, S100, S120, S140, S160, S XXS

STANDARD: ASME B16.5

MATERIAL GRADES:

- Nickel Alloys: Incoloy (800, 800H, 800HT, 825), Inconel (600, 625), Monel 400

- Specialty Alloys: Alloy 20, Hastelloy (C22, C276), Copper nickel (Cu-Ni), Titanium (Gr. 1, 2, 3), Urea Grade

- Duplex & Super Duplex: F51, F53, F55, F44

- Stainless Steel: AISI 304, 316, 321, 347

- Carbon Steel: ASTM A105, A350 LF2, A516 Gr.70, A694 F60–F65

Hunter Steel Flanges manufactures high-quality Reducing Flanges designed to connect piping systems with different nominal pipe sizes while maintaining proper pressure and flow characteristics. These flanges are available in various configurations such as weld neck, slip-on, and threaded, depending on installation requirements.

Reducing flanges are ideal for compact piping layouts, where space is limited or where smooth transition between different pipe sizes is critical. They are commonly used in oil & gas, petrochemical, chemical, and power generation applications. Engineered to meet ASME B16.5 and other international standards, our reducing flanges ensure durability, dimensional accuracy, and leak-proof connections across pressure classes and material grades.

SIZES: ½” to 60”

SIZES: ½” to 60”

CLASS: 150 to 2500; 2500PSI to 15000PSI

TYPE: Expander Weld Neck Flange

SCHEDULE: S10, S20, S30, S40, S STD, S60, S XS, S80, S100, S120, S140, S160, S XXS

STANDARD: ASME B16.5 | API 6A

MATERIAL GRADES:

- Nickel Alloys: Incoloy (800, 800H, 800HT, 825), Inconel (600, 625), Monel 400

- Specialty Alloys: Alloy 20, Hastelloy (C22, C276), Copper nickel (Cu-Ni), Titanium (Gr. 1, 2, 3), Urea Grade

- Duplex & Super Duplex: F51, F53, F55, F44

- Stainless Steel: AISI 304, 316, 321, 347

- Carbon Steel: ASTM A105, A350 LF2, A516 Gr.70, A694 F60–F65

Hunter Steel Flanges provides precision-made Expander Flanges, engineered to increase the pipe size at the flange connection without requiring an additional reducer or welding. These flanges are primarily used in pump and compressor connections, where an upgrade in line size is required for flow optimization.

Expander flanges serve as an excellent alternative to a separate weld neck flange and concentric reducer, offering a compact and cost-effective solution. They are widely used in chemical, petrochemical, water treatment, and oil & gas industries for smooth transitions from smaller to larger pipe diameters. Manufactured to ASME B16.5 and other global standards, our expander flanges ensure structural integrity, reliable sealing, and precise dimensional compatibility.

SIZES: ½” to 24”

SIZES: ½” to 24”

CLASS: 150 to 2500;

TYPE: Weldo Flange, Nipo Flange

SCHEDULE: S10, S20, S30, S40, S STD, S60, S XS, S80, S100, S120, S140, S160, S XXS

STANDARD: ASME B16.5 | MSS-SP 97

MATERIAL GRADES:

- Nickel Alloys: Incoloy (800, 800H, 800HT, 825), Inconel (600, 625), Monel 400

- Specialty Alloys: Alloy 20, Hastelloy (C22, C276), Copper nickel (Cu-Ni), Titanium (Gr. 1, 2, 3), Urea Grade

- Duplex & Super Duplex: F51, F53, F55, F44

- Stainless Steel: AISI 304, 316, 321, 347

- Alloy Steel: AISI Gr.1, Gr.5, Gr.9, Gr.11, Gr.22, Gr.91

- Carbon Steel: ASTM A105, A350 LF2, A516 Gr.70, A694 F60–F65

Weldo Flange

A Weldo Flange is a combination of a weld neck flange with integral O-let fitting. It is used as a branch connection and is directly welded to the run pipe, ensuring high integrity in high-pressure applications. Weldo flanges provide a smooth flow transition from the header to the branch line and are commonly used in refineries, chemical plants, and offshore facilities.

Nippo Flange

A Nippo Flange is an integration of a welding nipple and a flange, often used for branch connections where space is limited. It is ideal for high-pressure systems requiring strong welded joints. The compact and sturdy design makes Nippo flanges suitable for applications in oil & gas, petrochemical, and power generation industries.

Customization Available: Tailor-made solutions for barrel length, bore size, bevel ends, and flange faces (RF, RTJ, FF) to suit your project needs.

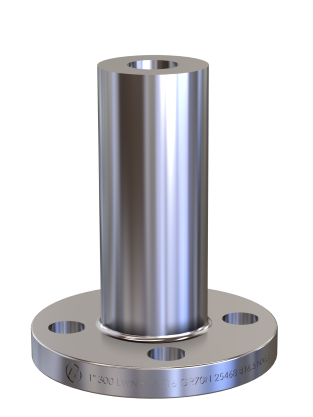

SIZES: ½” to 60”

SIZES: ½” to 60”

CLASS: 150 to 2500

TYPE: Long Weld Neck (LWN) – Straight & Heavy Barrel Types

SCHEDULE: S10, S20, S30, S40, S STD, S60, S XS, S80, S100, S120, S140, S160, S XXS

STANDARD: ASME B16.5

MATERIAL GRADES:

- Nickel Alloys: Incoloy (800, 800H, 800HT, 825), Inconel (600, 625), Monel 400

- Specialty Alloys: Alloy 20, Hastelloy (C22, C276), Copper nickel (Cu-Ni), Titanium (Gr. 1, 2, 3), Urea Grade

- Duplex & Super Duplex: F51, F53, F55, F44

- Stainless Steel: AISI 304, 316, 321, 347

- Alloy Steel: AISI Gr.1, Gr.5, Gr.9, Gr.11, Gr.22, Gr.91

- Carbon Steel: ASTM A105, A350 LF2, A516 Gr.70, A694 F60–F65

Hunter Steel Flanges offers precision-engineered Long Weld Neck Flanges (LWN) designed for high-pressure, high-temperature applications requiring seamless flow and enhanced reinforcement. These flanges are ideal for critical process piping systems, pressure vessels, and heat exchangers. Available in a wide range of sizes, pressure classes, and material grades, our LWN flanges meet stringent international standards and can be customized for straight or heavy barrel configurations based on client specifications.

Our Business Hours

We are here to serve you during the following business hours:

Monday to Saturday: : 8 to 6 pm

Phone: +97148877711

Contact Us Today

- You are here:

- Home /

- Hunter Steel Flanges /

- Special Flange

Quality Department

Hunter Steel Flanges Manufacturing LLC. is certified under ISO 9001:2015, ISO 14001:2015, OHSAS 18001 / ISO 45001. Also, all of our products are compliance with the requirements of ANSI/ASME, API, JIS, AWWA, DIN, BS and special requests.