COMMITMENT

Customer commitment

Read More...

INTEGRITY

Highest standards of integrity

Read More...

QUALITY

Unsurpassed products & services

Read More...

TEAMWORK

See What We're Up To

Read More...

SIZES : 3” to 6”

SIZES : 3” to 6”

SCHEDULE : S10, S20, S30, S40, S STD, S60, S XS, S80, S100, S120, S140, S160, S XXS

STANDARD : API | ASTM | DIN | EN | AS PER CLIENT DRAWING

MATERIAL GRADE : Stainless steel (AISI 304, 316, 321, 347); Alloy steel (AISI Gr.1, Gr.5, Gr.9, Gr.91, Gr.11, Gr.22); Carbon steel (ASTM 105, A516/70, A350 LF2, A694 F60-65)

The advantages of clamp connectors compared with bolted flanges are; the small size and low weight, and the ease installation and assembly with only four bolts and a clamp assembly which can be rotated to the most convenient position for bolt pre-loading. In the oil and gas industry, clamp connectors are often used in flowlines and other high pressure systems and where the compact design and small sealing diameter is of greatest advantage.

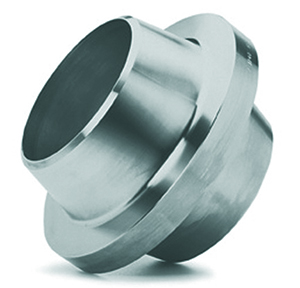

LONG NECK WELDING (LWN) / EXPANDER FLANGE / REDUCING FLANGE / WELDOFLANGE

SIZES : 3” to 12”

CLASS : 150 to 2500;

SCHEDULE : S10, S20, S30, S40, S STD, S60, S XS, S80, S100, S120, S140, S160, S XXS

STANDARD : API | ASTM | DIN | EN | AS PER CLIENT DRAWING

MATERIAL GRADE : Incoloy (800, 800H, 800 HT, 825), Alloy 20; Hastelloy (C22, C276); Cupronickel Cu-Ni; Monel 400; Inconel (600, 625); Titanium (Gr. 1, 2, 3); Urea Grade; Duplex -Super Duplex F51, F53, F55, F44; Stainless steel (AISI 304, 316, 321, 347); Alloy steel (AISI Gr.1, Gr.5, Gr.9, Gr.91, Gr.11, Gr.22); Carbon steel (ASTM 105, A516/70, A350 LF2, A694 F60-65)

ORIFICE PLATE

SIZES : 3” to 36”

SIZES : 3” to 36”

CLASS : 150 to 2500;

CLASS : 150 to 2500; 2500PSI to 15000PSI

STANDARD : API, ASME B16.5, ASME B16.48, API STD, MESC/ SHELL; CLIENT DRAWING

MATERIAL GRADE : Incoloy (800, 800H, 800 HT, 825), Alloy 20; Hastelloy (C22, C276); Cupronickel Cu-Ni; Monel 400; Inconel (600, 625); Titanium (Gr. 1, 2, 3); Urea Grade; Duplex -Super Duplex F51, F53, F55, F44; Stainless steel (AISI 304, 316, 321, 347); Alloy steel (AISI Gr.1, Gr.5, Gr.9, Gr.91, Gr.11, Gr.22); Carbon steel (ASTM 105, A516/70, A350 LF2, A694 F60-65)

ORIFICE FLANGE

FLANGES (FROM SOLID BAR & FORGING)

Sizes : 3” to 36”

CLASS : 150 to 2500;

TYPE : WELDNECK, SOCKET WELD, THREADED

SCHEDULE : S10, S20, S30, S40, S STD, S60, S XS, S80, S100, S120, S140, S160, S XXS

STANDARD : API | ASTM | DIN | EN | AS PER CLIENT DRAWING

MATERIAL GRADE : Incoloy (800, 800H, 800 HT, 825), Alloy 20; Hastelloy (C22, C276); Cupronickel Cu-Ni; Monel 400; Inconel (600, 625); Titanium (Gr. 1, 2, 3); Urea Grade; Duplex -Super Duplex F51, F53, F55, F44; Stainless steel (AISI 304, 316, 321, 347); Alloy steel (AISI Gr.1, Gr.5, Gr.9, Gr.91, Gr.11, Gr.22); Carbon steel (ASTM 105, A516/70, A350 LF2, A694 F60-65)

SIZES : 3” to 36”

SIZES : 3” to 36”

CLASS : 150 to 2500;

MATERIAL GRADE : Incoloy (800, 800H, 800 HT, 825), Alloy 20; Hastelloy (C22, C276); Cupronickel Cu-Ni; Monel 400; Inconel (600, 625); Titanium (Gr. 1, 2, 3); Urea Grade; Duplex -Super Duplex F51, F53, F55, F44; Stainless steel (AISI 304, 316, 321, 347); Alloy steel (AISI Gr.1, Gr.5, Gr.9, Gr.91, Gr.11, Gr.22); Carbon steel (ASTM 105, A516/70, A350 LF2, A694 F60-65)

Anchor Flanges are used to anchor pipe - often when crossing streams or ravines. They are a double hub piece of steel that is put into a special holder that is part of a piling to supports the pipeline and resist loading. The anchor structure is welded to the pipe and usually embedded in concrete.

Anchor flanges actually contain axial thermal expansion – that is axial thrust in pipelines. The assumed design temperature change is 90 degrees Fahrenheit. The thrust is transferred to the anchor foundation –in which the anchor is mounted. These flanges are used at crossings and points with changes in pipeline direction.

Our Business Hours

We are here to serve you during the following business hours:

Monday to Saturday: : 8 to 6 pm

Phone: +97148877711

Contact Us Today

- You are here:

- Home /

- Hunter Steel Flanges /

- Special Piping Product

Quality Department

Hunter Steel Flanges Manufacturing LLC. is certified under ISO 9001:2015, ISO 14001:2015, OHSAS 18001 / ISO 45001. Also, all of our products are compliance with the requirements of ANSI/ASME, API, JIS, AWWA, DIN, BS and special requests.